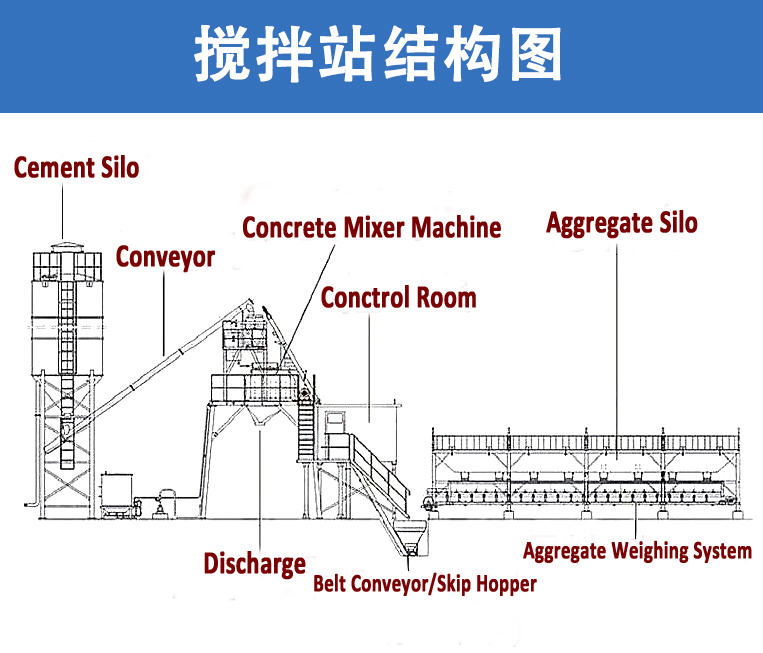

Concrete Batching Plant Parts

Concrete batching plant parts include concrete mixing machine, material weighing system, conveying system, storage system, control system and other add on structure. Today, let us see the detailed information of concrete batch plant parts.

Concrete mixing plant mainly consists of the following main parts, and each part has its specific function:

1, Mixing host:

This is the core part of the concrete batching plant components, which is used to mix various raw materials (such as cement, aggregate, water, etc.) into concrete. The mixing machine usually adopts double horizontal shaft forced concrete mixer, which can mix the concrete efficiently and evenly to ensure the quality and stability of concrete.

2, Material weighing system:

This system is responsible for the precise measurement of various raw materials to ensure the quality and accurate proportion of concrete. The weighing system is characterized by high precision and reliability, which can effectively ensure the accurate proportioning of concrete without affecting the quality of the final concrete product.

3, Material conveying system:

This system includes belt conveyor, bucket elevator, screw conveyor and other equipments, which are used to convey all kinds of raw materials and concrete to the designated location. The high efficiency, stability and reliability of the material conveying system ensure the smooth running of the production.

4, Material storage system:

Including cement silo, aggregate silo, powder silo, etc., which are used to store various raw materials. These storage equipments ensure the continuous and stable supply of raw materials to meet the demand of the mixing host.

5, Control system:

It is the command center of the whole concrete batching plant, responsible for centralized control and monitoring of each part. The control system can automate the operation of the concrete batching plant, including turning on and off the equipment, regulating the mixing time, checking the quality of concrete, etc., so as to ensure the smooth running of the production.

6, In addition, the concrete batching plant may also include some non-essential components, such as additive delivery system, dust removal system, water filling system, etc. These systems can be configured according to the actual production requirements to improve production efficiency and product quality.

Overall, the various concrete batching plant parts collaborate with each other to complete the concrete production task and ensure that the concrete produced is of stable quality and accurate proportion to meet the needs of engineering construction.

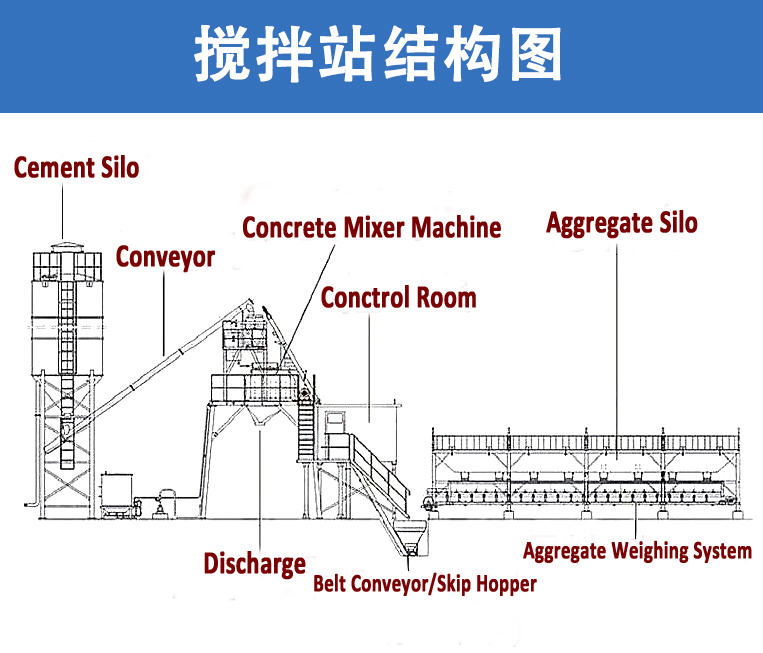

Concrete mixing plant mainly consists of the following main parts, and each part has its specific function:

1, Mixing host:

This is the core part of the concrete batching plant components, which is used to mix various raw materials (such as cement, aggregate, water, etc.) into concrete. The mixing machine usually adopts double horizontal shaft forced concrete mixer, which can mix the concrete efficiently and evenly to ensure the quality and stability of concrete.

2, Material weighing system:

This system is responsible for the precise measurement of various raw materials to ensure the quality and accurate proportion of concrete. The weighing system is characterized by high precision and reliability, which can effectively ensure the accurate proportioning of concrete without affecting the quality of the final concrete product.

3, Material conveying system:

This system includes belt conveyor, bucket elevator, screw conveyor and other equipments, which are used to convey all kinds of raw materials and concrete to the designated location. The high efficiency, stability and reliability of the material conveying system ensure the smooth running of the production.

4, Material storage system:

Including cement silo, aggregate silo, powder silo, etc., which are used to store various raw materials. These storage equipments ensure the continuous and stable supply of raw materials to meet the demand of the mixing host.

5, Control system:

It is the command center of the whole concrete batching plant, responsible for centralized control and monitoring of each part. The control system can automate the operation of the concrete batching plant, including turning on and off the equipment, regulating the mixing time, checking the quality of concrete, etc., so as to ensure the smooth running of the production.

6, In addition, the concrete batching plant may also include some non-essential components, such as additive delivery system, dust removal system, water filling system, etc. These systems can be configured according to the actual production requirements to improve production efficiency and product quality.

Overall, the various concrete batching plant parts collaborate with each other to complete the concrete production task and ensure that the concrete produced is of stable quality and accurate proportion to meet the needs of engineering construction.

This resource is from http://www.haomeibatchingplant.com/News/concrete-batching-plant-parts.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: nydia@concretebatchplant24.com

评论

发表评论